WELDING SIMULATOR

SANLAB Learning's welding simulator provides students with a realistic welding experience using VR-AR technology, offering a safe and controlled training environment. With precise mask and torch tracking, detailed analyses, and instant feedback, it enables students to develop their skills and prepare for real welding conditions.

Welding Training Simulator

The Welding Simulator is an advanced VR-AR based training system designed for vocational and industrial education environments. Equipped with high-precision motion tracking technology, it delivers a highly realistic and immersive welding experience. Trainees can safely develop their welding skills in a controlled and interactive virtual environment.

This next-generation simulator provides hands-on practice across various welding processes, offering accurate torch and mask tracking for real-time performance monitoring. Integrated electronics ensure precise motion detection, enhancing welding accuracy and improving skill development.

System supports in-depth training scenarios that help students refine their technique while reducing operational risks and training costs.

- VR-AR technology providing a controlled and interactive welding training environment

- High-precision torch and mask tracking system performance

- Realistic welding environment with real-time error detection

- Supports multiple welding processes (SMAW, MIG/MAG, TIG, FCAW)

Scenerios

SMAW-Shielded Metal Arc Welding

MIG-Metal Inert Gas Welding

TIG-Tungsten Inert Gas Welding

FCAW-Flux-Cored Arc Welding

Training Scenarios

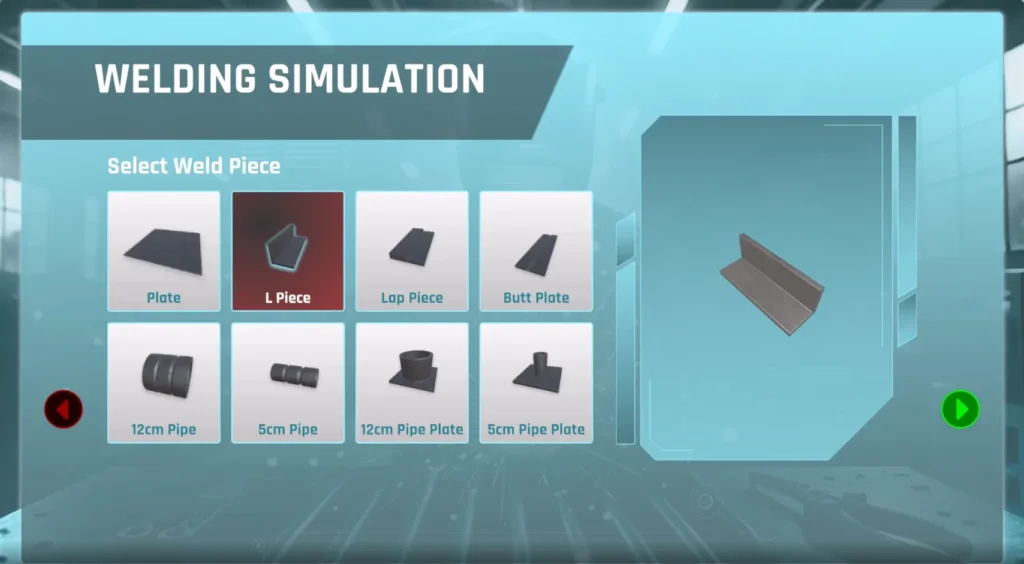

Welding simulator provides multiple training scenarios to replicate real-world welding tasks. Trainees can practice different welding positions, materials, and joint configurations in a controlled virtual environment.

System continuously monitors key welding parameters in real time, offering immediate feedback to help improve technique, ensure proper penetration, and maintain weld quality.

Monitored Parameters:

- Torch Movement Speed: Tracks torch speed for better penetration.

- Torch Angle & Position: Monitors angle and position to ensure accurate welding.

- Arc Length Distance: Measures arc-to-workpiece distance to maintain stability.

- Work Distance: Checks distance to material for consistent weld quality.

Welding Types & Material Types

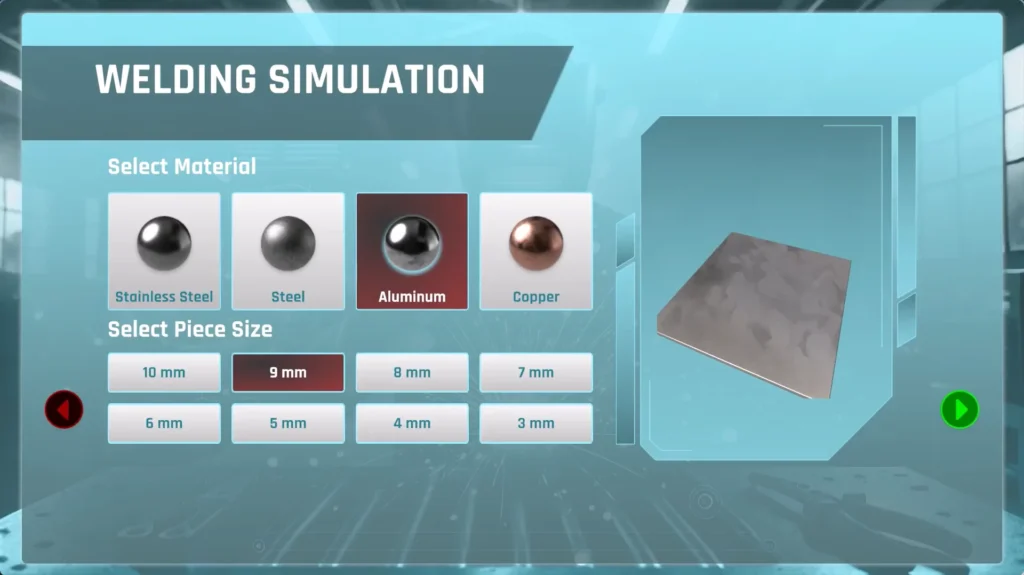

The simulator supports different welding types and materials for vocational training. Trainees can practice each welding process with real-time monitoring of relevant parameters.

Welding Types:

- SMAW (Shielded Metal Arc Welding)

- MIG/MAG (Metal Inert/Active Gas)

- TIG (Tungsten Inert Gas)

- FCAW (Flux-Cored Arc Welding)

Training is possible with different material types, replicating their properties in the virtual environment. Trainees can practice on a variety of workpieces, including 5 cm and 12 cm pipe plates, 5 cm and 12 cm pipes, butt plates, L pieces, lap pieces, and standard plates.

Material Types:

- Steel

- Stainless Steel

- Aluminum

- Copper

Application Areas

Welding simulator is applied across multiple industries and training environments. In the manufacturing and automotive sector, it delivers standardized and safe instruction for new hires and experienced welders, ensuring consistent skill development, reducing material waste, and supporting compliance without interrupting operations.

For technical and vocational schools, it enables students to practice real-world welding skills in an immersive virtual environment, lowering material costs and ensuring safety.

In industrial training centers, the simulator enhances workforce training by replicating real-world welding scenarios in a controlled environment, improving efficiency and minimizing safety risks.

Workforce development programs benefit from flexible, role-specific modules that support skill-building, reskilling, and job placement, making it suitable for entry-level and returning workers.

In shipbuilding training centers, the simulator prepares trainees for complex welding tasks such as overhead and confined-space welding, fostering confidence, safety awareness, and adherence to shipyard standards.

Hardware Components of Welding Simulator

- VR Headset

- Touch Secreen

- Simulation Computer

- Welding Simulation Software

- 4 Torchs

- Worktable

- Work Pieces

- Monitor

Learn More

Download Product Catalogue

Portable Welding Simulator

A compact VR-AR welding simulator for mobility and hands-on training without a PC. Includes a backpack-sized headset, foldable table, controller-based torch, welding mask, and touchscreen interface. Supports SMAW, MIG/MAG, TIG, and FCAW processes, with multiple optional workpieces for various welding positions. Lightweight and portable, it allows quick setup and training anywhere—classrooms, field demos, or industrial sites.

- Standalone VR/AR headset

- Foldable training table

- Controller-based torch

- Touchscreen with session recording

- 14+ optional workpieces

- Supports SMAW, MIG/MAG, TIG, FCAW

- Lightweight and portable

Quantification and Consideration

Institution Name

Trainer Name

Measurement and Quality Control

Course Data

Student Name

Couse Date

Course Duration

Completed Lessons Report